CONTACT-US

for a quote

0033 (0)4 74 80 19 33

commercial@sodafom.com

or

Copper and alloys

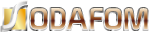

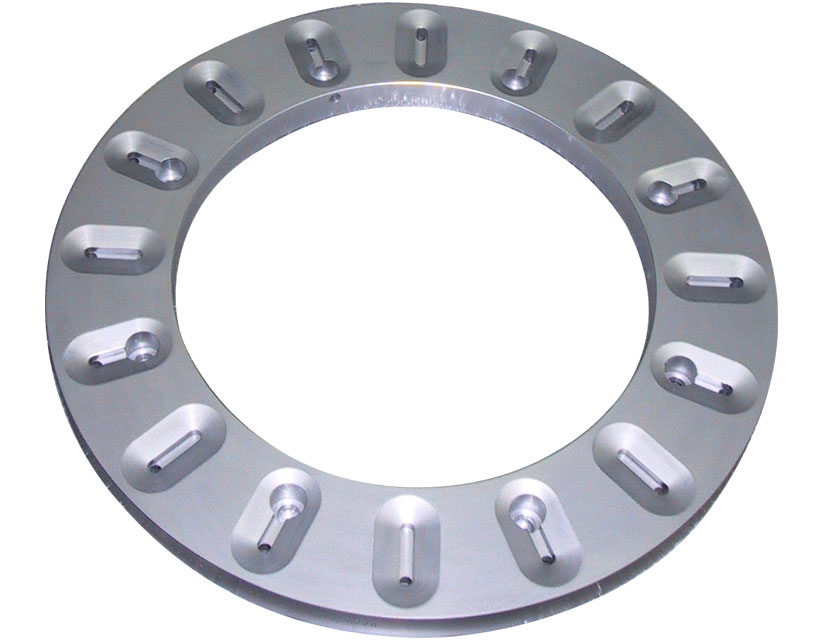

ZA 40 U3 PIECES

Castings techniques

- Sand moulding:

- One-off parts, small and medium runs.

- Shell moulding:

- medium and large production runs.

Some applications:

Manufacture of bushes for all industries.

Mines and metal industry, stone and cement industry. Press manufacture.

Automobile manufacture. Crane manufacture. Building construction machines.

Technical and physical characteristics

Zinc-Aluminium-Copper Alloy

- Density: 4,4.

- Tensile strength: 26 to 32 MPa/mm².

- Breaking elongation: 1 to 4%.

- Brinell-Hardness: 90 to 130 HBS.

- Elasticity limit: 19 à 23 Mpa/mm².

- Compressive strength: 50 Mpa/mm².

- Endurance strength: 3 à 4 Mpa/mm².

- Electrical conductivity: 16,6 m/Ohm/ mm².

- Electrical resistance: 0,06 Ohm mm²/m.

- Thermal conductivity:

0,24 à 0,26 cal/cm sec °C. - Linear dilatation coefficient for 20 to 100°C: 22 à 24 x 106

- Magnetic permeability:

1,01 0,4 x 106 WB/mE / A/m - Skrinkage: environ 1,3%.

- Max. PV with continuous load:

approx. 400 kgm / cm2 sec - Maximum operating temperature: 150°C.

Comparison chart

Technical values for cast bronze (Standard DIN 1705).

| Alloy | UE14 | UE13 | ZA40U3 |

| Brinell-Hardness | 85 to 115 | 80 to 95 | 90 to 130 |

| Tensile strength | 20 to 25 | 24 to 28 | 25 to 32 |

| Breaking elongation | 3 to 5 | 8 to 15 | 1 to 4 |

| Density | 8,6 | 8,6 | 4,4 |